Manufacturing

Introduction

The Manufacturing module (also known as MRP – Manufacturing Resource Planning) is a fully integrated system used to manage production operations within a company. It allows you to control manufacturing orders, manage bill of materials (BoM), track work orders, schedule production based on real-time demand, and handle subcontracting and quality control efficiently.

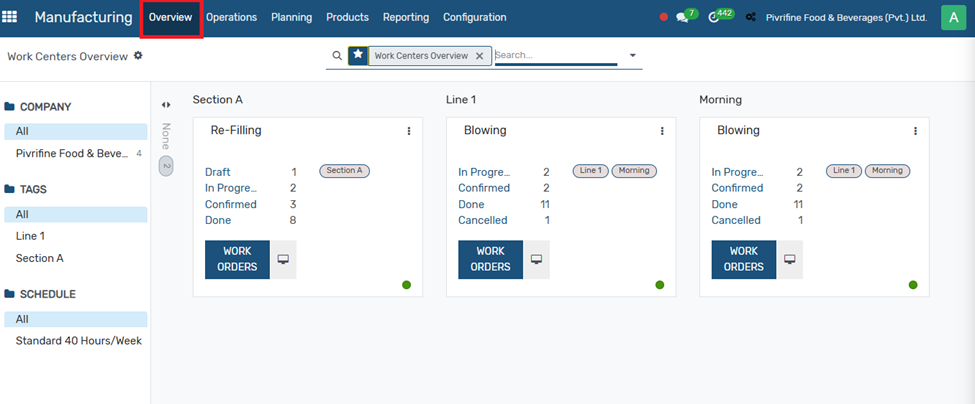

Overview:

The Overview in Manufacturing is a centralized dashboard that displays the status of all Work Centers and Work Orders in real time.

It helps you:

- Track the progress of manufacturing operations.

- Monitor machine and labor efficiency, and manage ongoing and upcoming production tasks.

Click on the Manufacturing module showing on the dashboard.

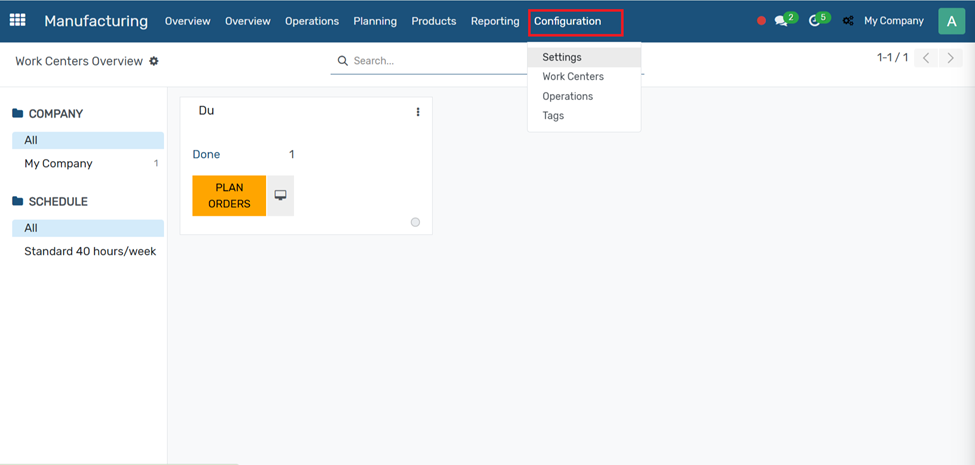

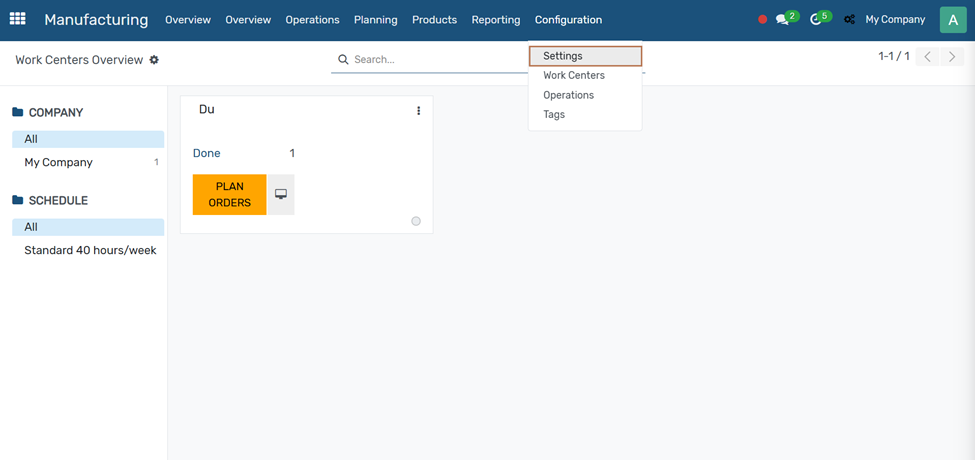

Configuration:

- The basic setting must be configured before starting work in the manufacturing module.

Setting:

Enable the following options as needed:

- Work Orders – to manage step-by-step operations.

- Quality Checks – if you want to inspect products during production.

- Subcontracting – to outsource some production steps.

- Master Production Schedule – to plan future production.

- Barcode – for barcode scanning during production (optional).

Click Save.

This manual serves as a user guide for configuring and using the Manufacturing module, aimed at production managers, planners, operators, and ERP administrators. It covers setup, everyday operations, and best practices for efficient production.

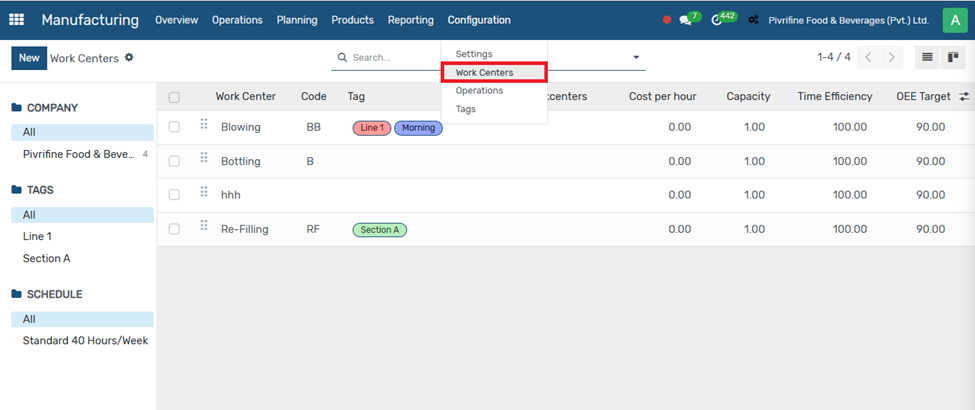

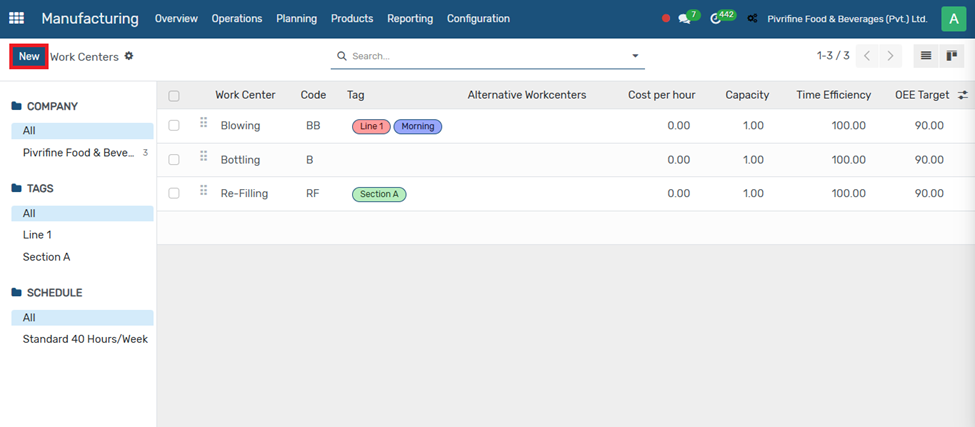

Work Center:

a Work Center refers to a specific physical or logical location in a production environment where operations or manufacturing processes occur. A Work Center could be a machine, assembly line, or a person who performs a specific task in the production process.

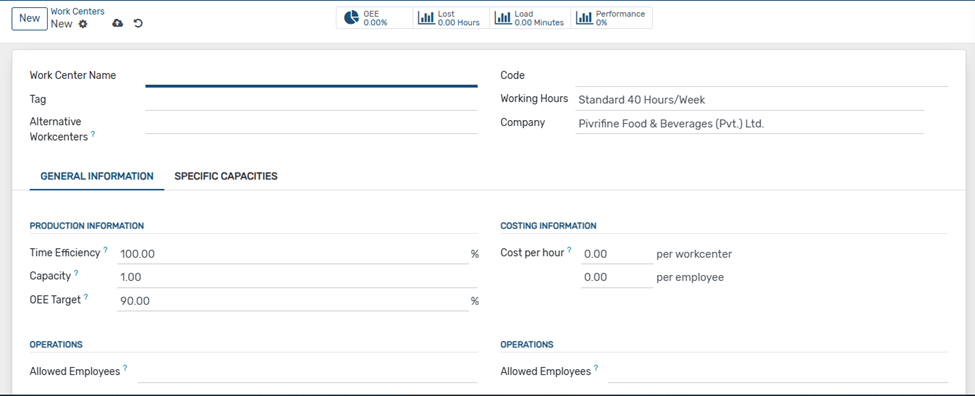

Click on the New button to define a new Work Center.

When you create or edit a Work Center in the following key fields will need to be filled in:

- Work Center Name

- Work Center Type

- Work Center Cost

- Time Efficiency

- Capacity

Click on the Save button to save your information.

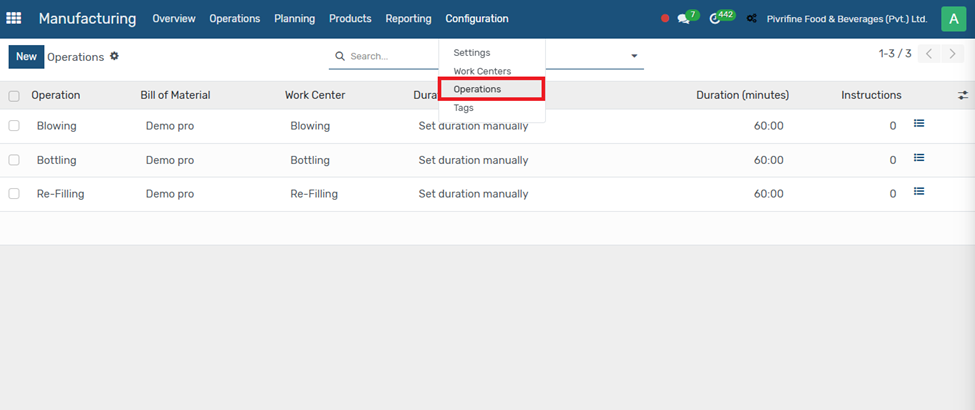

Operations:

Operations refer to the specific steps or activities carried out to produce a product. Each operation defines what is done, where it’s done, and how long it takes during the manufacturing process.

An Operation represents a single task or phase within the production of a product — for example:

- Cutting

- Welding

- Assembly

- Painting

- Quality Check

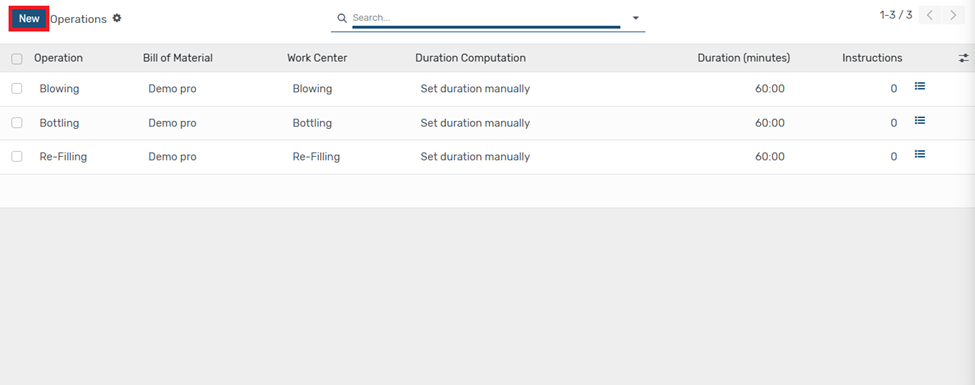

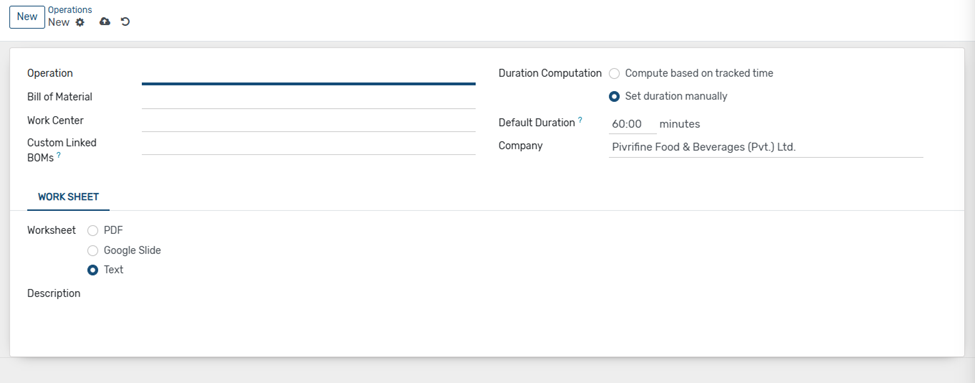

Now click on the Configuration under the configuration sub menu you can see Operation click on it.

Now click on the New button to create a new operation.

Now fill the following form.

- Operation

- Bill of Material

- Work Center

- Duration

- Default Duration

Once you done it click on the Save button to save your information

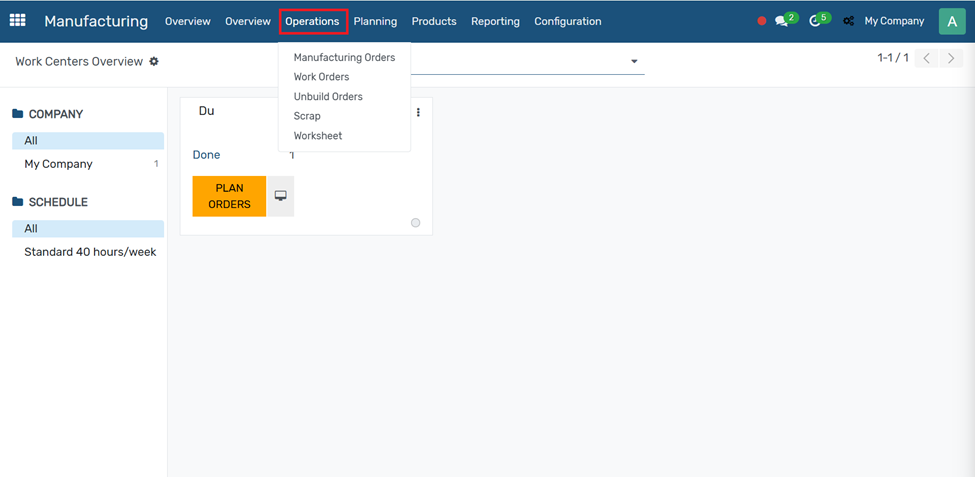

Operations:

Now click on the Operations and you will see a drop down menu.

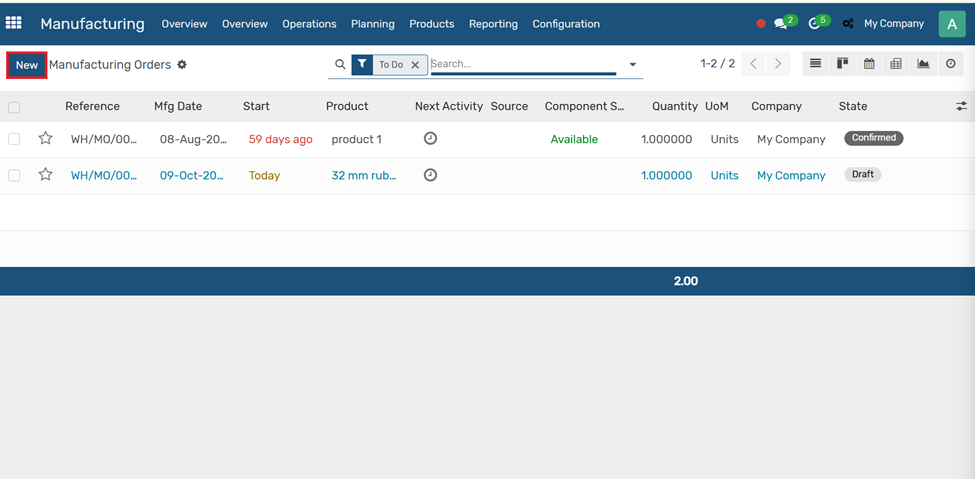

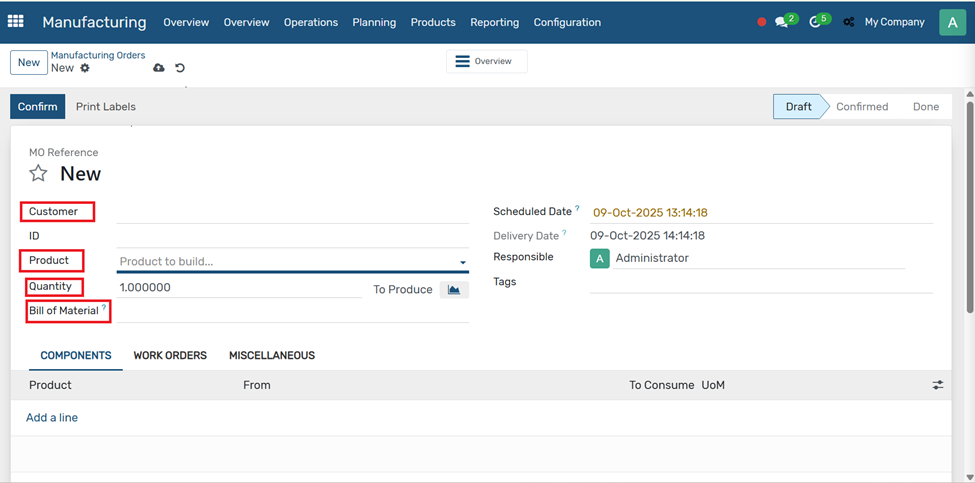

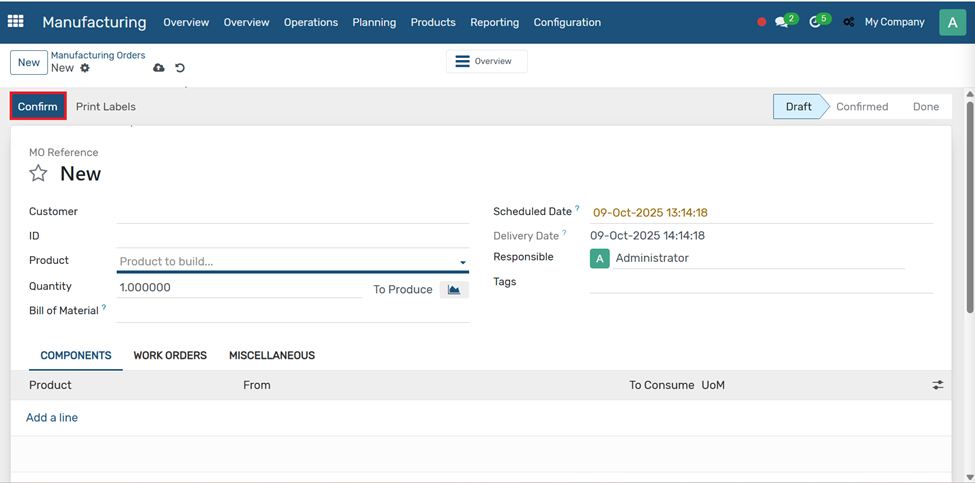

Now click on the New button for making a new manufacturing order.

Fill in the Manufacturing Order Details In the MO form:

- Product: Select the product you want to manufacture.

- Quantity to Produce: Enter how many units to make.

- Bill of Materials: It will auto-fill based on the selected product.

Customer: Set the desired Customer name.

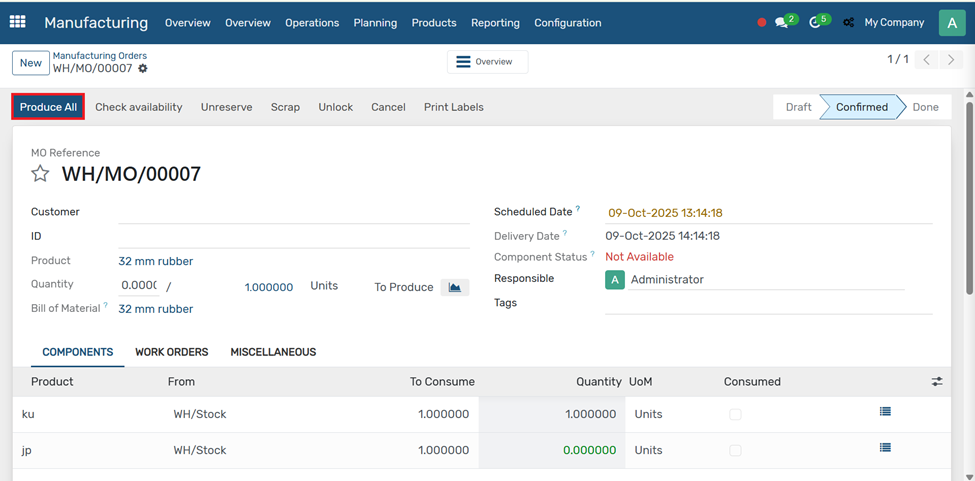

Click Confirm to validate the order.

After that click on Produce all it will go to done state

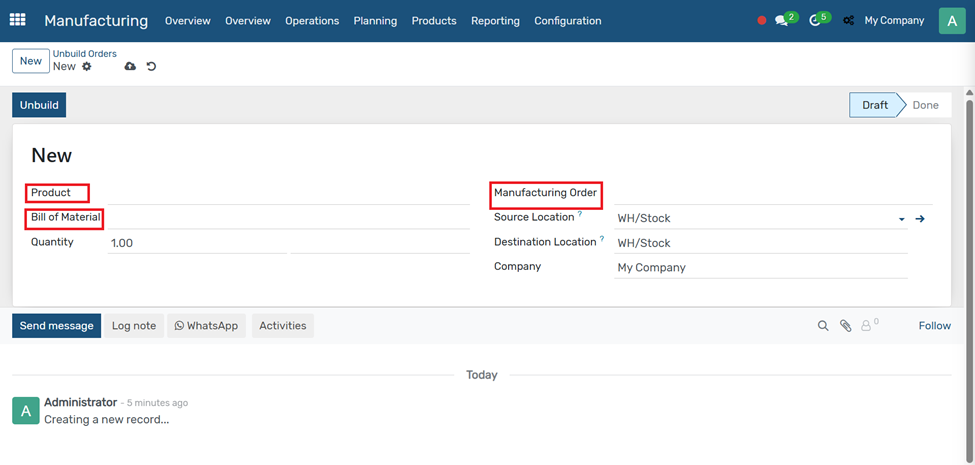

Unbuild Order:

You use it when you want to break down a finished product back into its parts (raw materials).

Configuration of Unbuild Order:

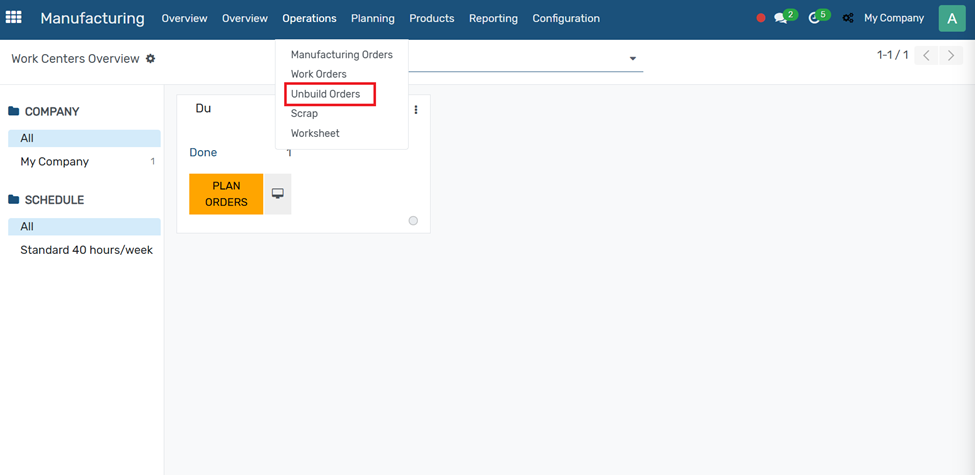

Click on the Operation button and into the drop down menu select Unbuild Order

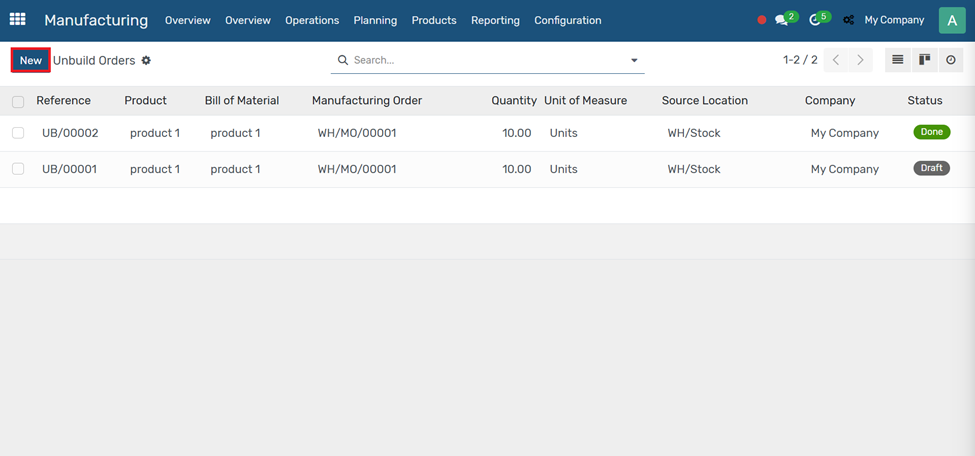

Click the New button to create an Unbuild Order

Fill in the following form:

- Product to Unbuild (e.g., Wooden Table)

- Bill of Materials (auto-selected if available)

- Manufacturing Order (optional — link it to the original MO)

Click Unbuild to confirm

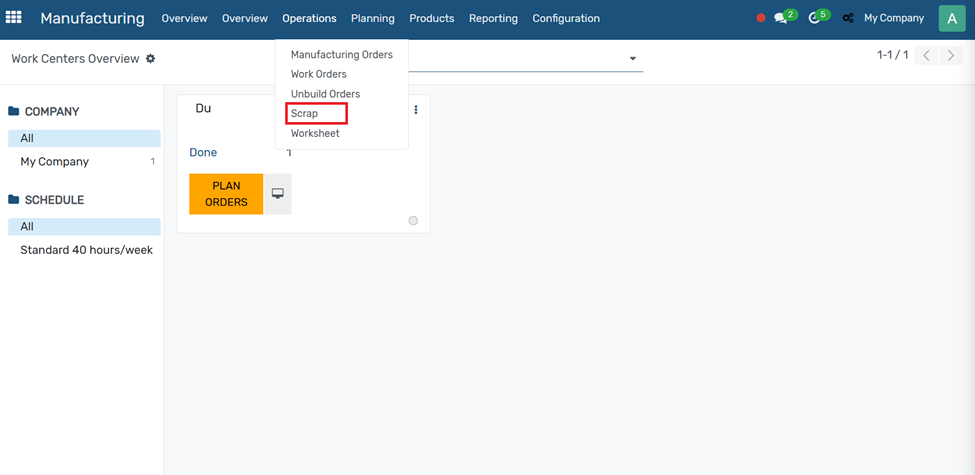

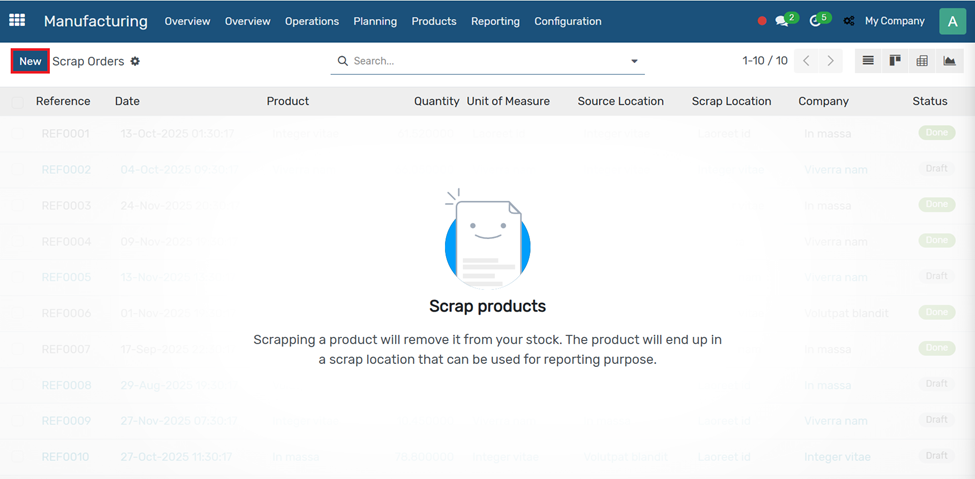

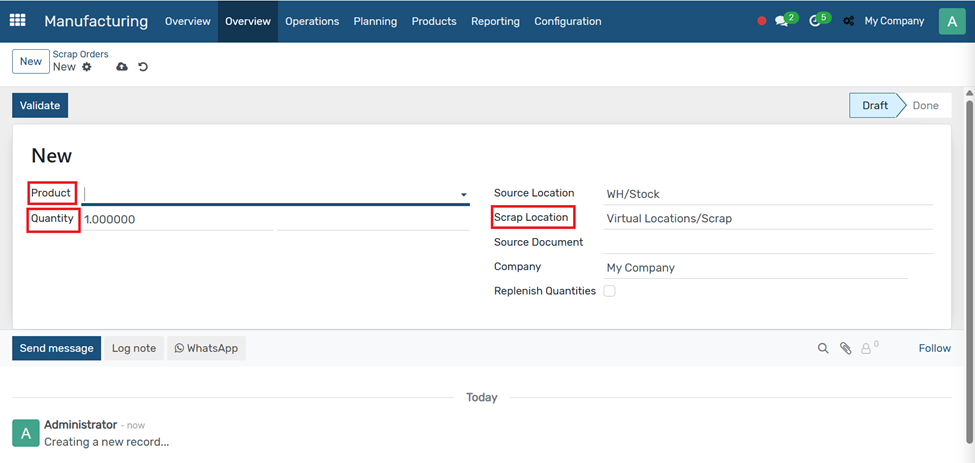

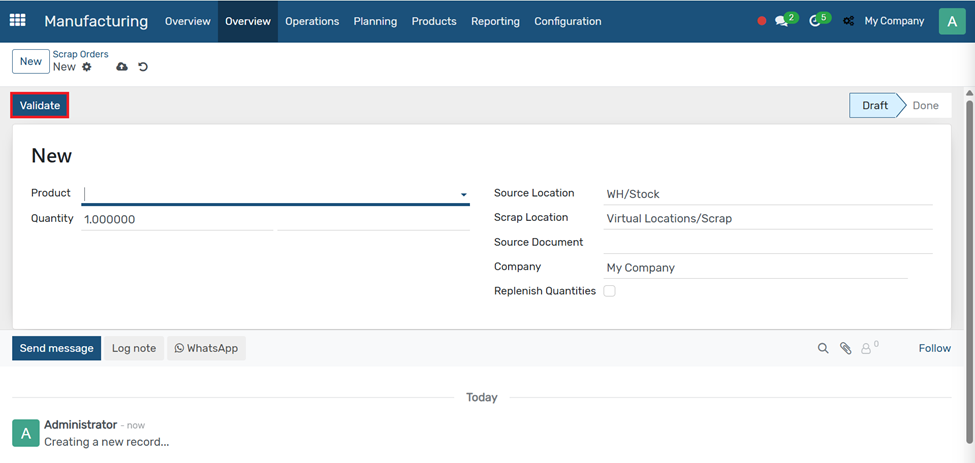

Scrap:

Scrap refers to any material or product that is damaged, defective, or unusable and cannot be used for production or sale. In Odoo, when you scrap an item, it is removed from available inventory and moved to a Scrap Location.

Click on the Scrap to create a new scrap form.

Now click on the New button to open the scrap form

Enter:

- Product to scrap

- Quantity

- Scrap Location (auto-filled usually)

Click Validate to confirm.

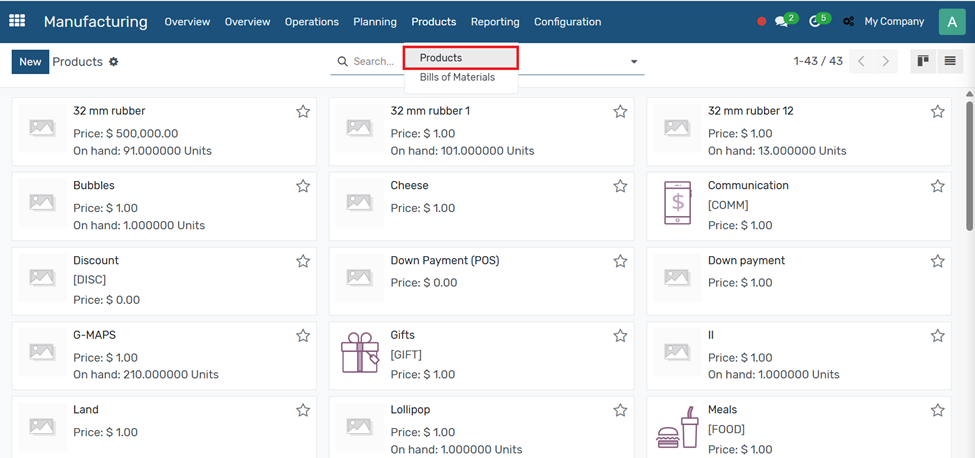

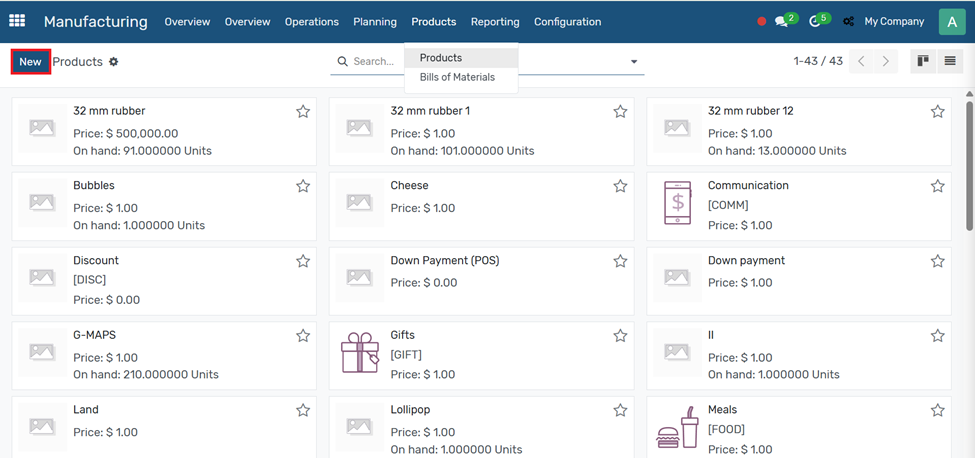

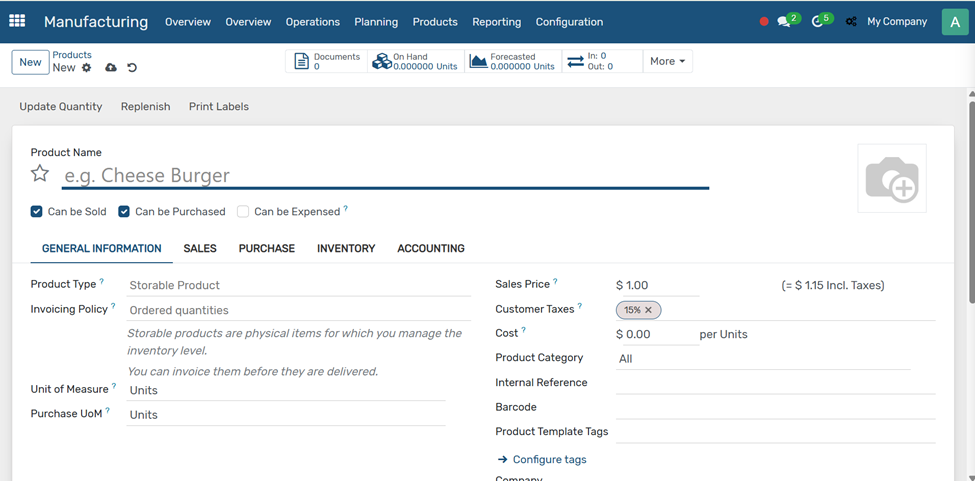

Product:

A Product is any item involved in your manufacturing process. It can be:

- Manufactured Product – the item you build (e.g., "Wooden Table")

- Component / Raw Material – the parts used to build something (e.g., "Table Legs", "Nails")

- Sub-Assembly – a product that is both made and used in another product (e.g., "Chair Frame")

- By-Product / Scrap – leftover or secondary output

Path:

Manufacturing → Products → Products → Click Create to add a new product

Now click on the New button to create a product.

- Give The product Type

- Invoicing policy

- Sales price

- Barcode

- Product template

- Internal reference

Bills of Materials:

A Bill of Materials (BoM) is a recipe or blueprint that lists:

- What raw materials/components are needed

- In what quantities

- Optionally, what operations (routing) must be done

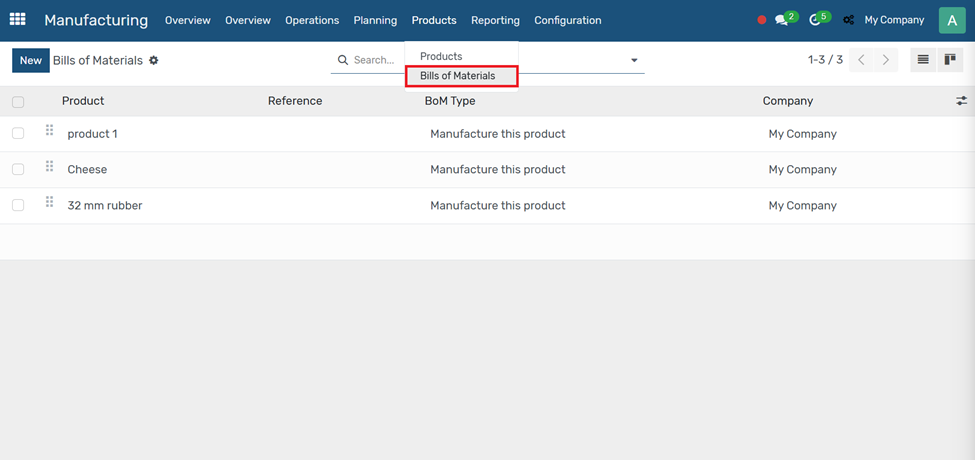

Path:

Manufacturing → Products → Bills of Materials

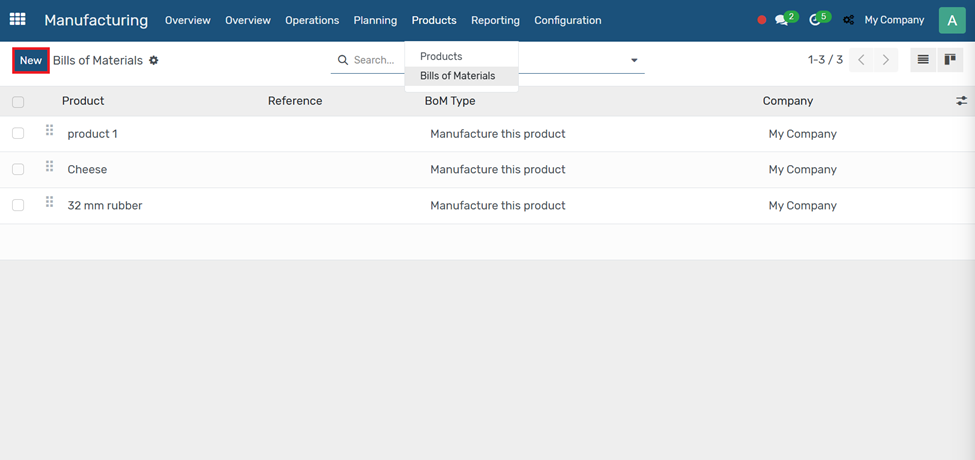

Click the New button to create a Bills of Materials.

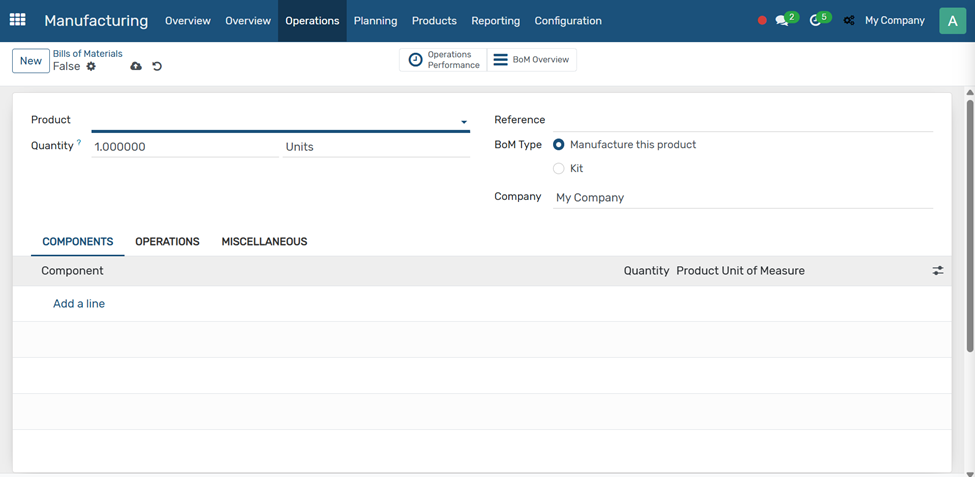

Enter the following details:

- Product

- Quantity

- BOM type

- Components

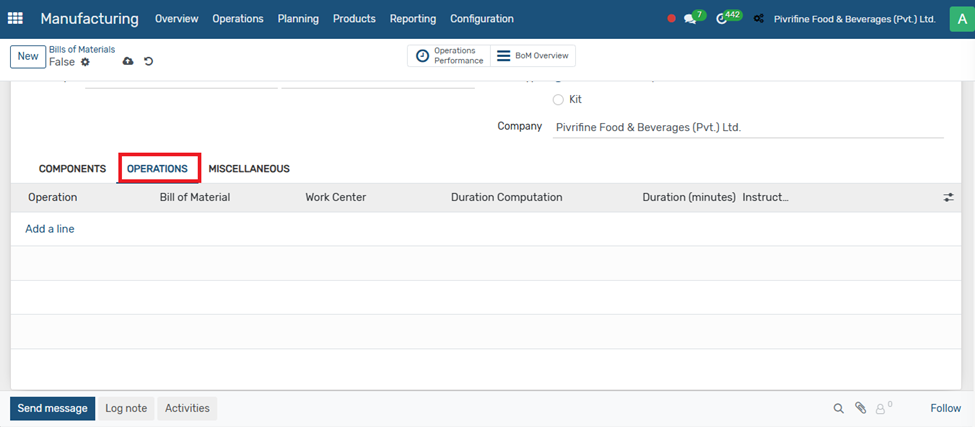

Operations:

Add the operation and work center

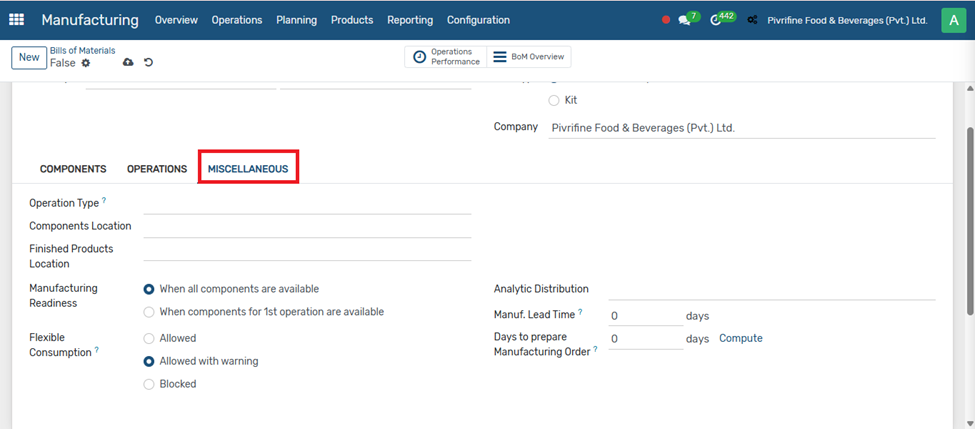

Miscellaneous:

Fill the following form:

- Operation Type

- Component Location

- Finished Products Location

Then click on the Save button to save your information